The Breath® is a fabric designed to absorb and break down harmful particles in the air: a cutting-edge technology capable of reducing air pollution caused by cars, heating systems, and industrial emissions.

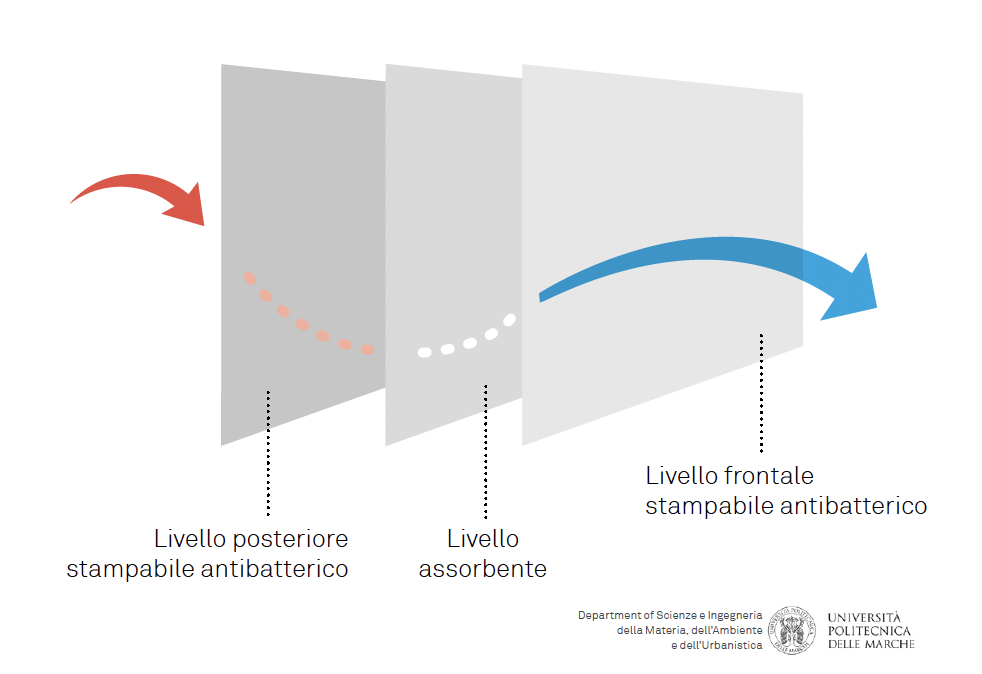

The fabric consists of three layers: the first layer facilitates air ventilation, the central layer captures and breaks down pollutant molecules, and finally, the last layer contains bactericidal agents.

Urban Vision is the only green media company in Europe that constructs all its installations with this special technology, providing a tangible contribution to improving air quality in our cities and protecting people’s health from the harmful effects of air pollution.

The Breath® utilizes the nano-molecules present in the atmosphere and the natural movement of oxygen particles to remove pollutant molecules. In cities, the lack of vegetation and the perpetual heating/cooling of materials used for buildings encourage the formation of air currents dense with pollutants. The Canyon effect thus generated significantly increases the absorption capacity of The Breath®.

The Breath® technology is designed to adapt to any indoor space, from the smallest room to large and very large volumes. The fabric enables the reduction of pollutants generated by heating systems and chemicals, creating a healthy and safe habitat.

Plastic bottles from post-consumer collection are washed, chopped, and transformed into confetti. The obtained confetti is melted down, turned into fine fibers, and then purified to produce a new raw material. The material is finally spun, woven, and coated with acrylic coatings.

In addition to preventing the release of phthalates and volatile organic compounds (VOCs), the creation of a material from recycled PET allows for a reduction in CO2 emissions and water consumption during the production process, compared to conventional fabrics.

Water-based latex inks are innovative in terms of environmental respect, health, and safety, allowing for minimal waste and downtime.

In May 2024, Urban Vision obtained the UNI/PdR 125:2022 certification, which confirms the company’s commitment to creating a fair and inclusive working environment. This certification recognises our policies and practices aimed at ensuring gender equality, solidifying our dedication to promoting equal professional growth for all employees.